TRISIM TECHNOLOGIES HAS BEEN WORKING IN THE FOLLOWING SOLUTION AREAS

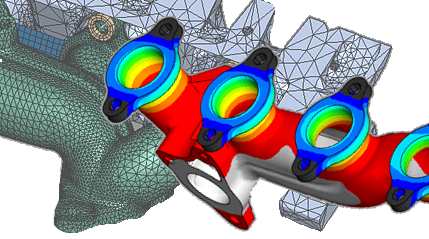

Engineering consultancy and simulation services

- Consultancy: TRISIM has been active in working with number of manufacturing companies in helping them develop simulation models for various product performance evaluation and manufacturing process simulation projects. Our expertise is in chemicals, process, pharmaceuticals, oil and gas, HVAC and industrial equipment industries with specific applications related to heat transfer, fluid flow, reactions, mixing, separation, and drying process modelling. We have developed relationships with number of global leaders in these industries where dedicated team of engineers is working on customer specific problems. We also take on project-based assignments which are performed by our in-house staff.

- Simulation Software support activities: Choice of simulation software plays a vital role in success of modelling and simulation initiatives in industry. TRISIM team helps customers with adoption of simulation software as part of their engineering design process. Our expertise plays a vital role in ensuring customers understand various key steps in simulation process and gain insight using simulation models. We help customers in every step of the way to ensure the best possible RoI on their software investments.

Embedded Case Studies

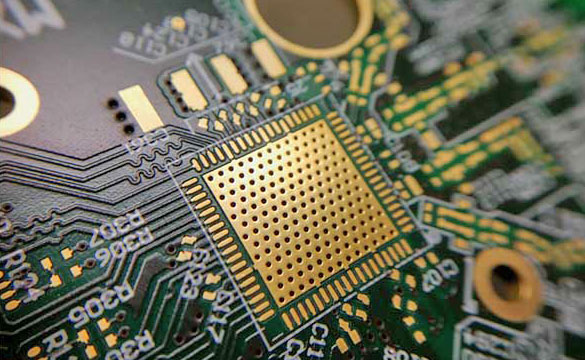

- Customised firmware and hardware development from concept to production for embedded systems. We designed a complete Data Acquisition System to monitor the environmental parameters in a pharmaceutical industry to maintain the specific environmental conditions throughout the premises

- Developed various Data Acquisition Systems, Sensor modules and sensors for the India Meteorological Department. These systems are deployed at all airports and have been successfully monitoring weather parameters for the IMD

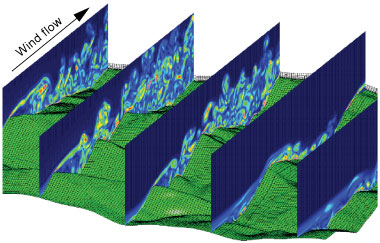

Customized Add-on software development

- Integrating “out of the box” simulation software in engineering design processes can be tough for many companies as it needs specialized know-how about working of the software. Hence many engineering companies prefer that only their R&D teams use the software for research and innovation and rest of the organization uses a standard operating process developed by experts. This process can be coded as a custom software so that chances of a errors can be eliminated. Emergence of public and private HPC cloud platforms has provided enormous opportunity to integrate these methods with the cloud solutions. Our experts have worked with industrial customers and software developers to develop such software tools for more than a decade. Our specific expertise is in the area of industrial mixing, HVAC modelling, wastewater treatment, and wind flow prediction etc.

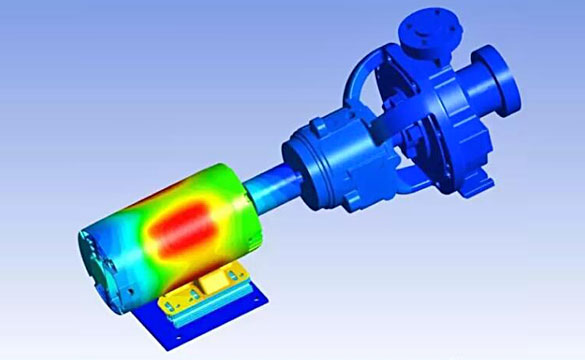

IoT and Digital twins

- Engineering simulation has so far been an off-line activity. However, with recent improvements in computational techniques and modern software architecture, it has become possible to bring simulation as part of on-line control and diagnostics activity by integrating it with widely available sensor data. The technique in broad terms has been referred as “Simulation Driven Digital Twin”. Simulation driven digital twins can be very useful in predictive maintenance as well as for remaining useful life prediction projects.

- Typically, a simulation driven digital twin is developed for known range of operating conditions of an equipment with predefined inputs and outputs. Digital twins integrate ROMs (reduced order models) and system models with signals received from the sensors to create a digital equivalent of an operating asset. Such a digital twin is then embedded in an IoT system. The twin then starts providing online output based on the available sensor data. The output can be in the form of temperature predictions, remaining useful life prediction or prediction of a potential run-away situation such as fire or an explosion. Alternatively, the twin can be used as a substitute to sensor data where the user wants to either complement the existing data (as it is insufficient) or does not believe that the data is accurate due to sensor limitations.

- We believe that there is a strong business case to study this further and develop this as a platform as well as “Application Specific Solution” e.g. specific solution for electric motors, pumps or high value industrial equipment etc. We are in building such an IoT enabled Digital twin platform with the help of industry and software providers.